Fully automatic liquid dispensing system, oral liquid dispensing tank, large infusion ingredient tank, reaction tank, concentration and dilution ingredient tank

- Beauty and makeup

- Cars and accessories

- Cosmetic&Beauty

- Electronic & digital

- Fashion clothing

- Furniture products

- garden, office/ meeting

- Gardening and Horticulture

- Home and daily

- Home decoration materials and lighting

- Jewelry

- Machinery&Hardware

- Office supplies

- Outdoor sport

- Pets

- Shoes, bags and accessories

- Toys and children's

Your shopping cart is empty!

Item specifics

- Applicable scope Large infusion oral liquid system

- Cylinder diameter Clumsy Bear

- Cylinder height seven hundred

- Heat exchange area zero point nine

- Is it a cross-border export exclusive source of goods no

- Mixing shaft power zero point three seven

- Mixing shaft speed 0~400

- Order number Z12678500

- Processing customization yes

- volume zero point two

- weight eighteen

Product Description

1、 Introduction to stainless steel mixing tank:

stainless steelA mixing tank is a fully enclosed container with upper and lower elliptical heads, mixing, jacket, and insulation. It is divided into several types: single-layer mixing, single-layer insulation mixing, jacket insulation mixing, and coil insulation mixing. All materials in contact with the material shall be useds31603Stainless steel plate ors30408Stainless steel plate, jacket and insulation skin are useds30408steel plate.The insulation material is aluminum silicate brocade,Perform sanitary mirror treatment on the inner wall of the cylinder to improve its roughnessRa<0.45umThe outer surface is polished with a matte finish, and the stirring system is sealed with a stainless steel hard alloy mechanical seal, which is pressure resistant, wear-resistant, and leak free. Fully comply with the Good Manufacturing Practice for DrugsGMPStandard. This device is mainly used for the preparation of oral liquids, pharmaceutical infusion solutions, small injections, and other drug formulations

2、 Product equipment composition:

This equipment is equipped with an electric heating system or steam heating, a main tank inner bucket, a stainless steel jacket, a sanitary grade conveying pump, a mixing motor, a reducer, a mixing base, a mixing system, a microporous filterPLCElectrical instrument control system and valve inside the tank, etcform.

3、 Liquid preparation tankmaintechnical parameter

Operating volume L | two hundred | three hundred | five hundred | one thousand | two thousand | three thousand | five thousand |

Full volume L | two hundred and fifty | four hundred | six hundred and thirty | one thousand three hundred and fifty | two thousand and five hundred | three thousand and eight hundred | five thousand and six hundred |

Design temperature ℃ | -40~350 | ||||||

Design pressure MPa | 0.09~0.35 | ||||||

Working pressure MPa | 0.1~1.6 | ||||||

Inner diameter/inner height mm | 600/700 | 700/800 | 900/800 | 1000/eight hundred | 1250/1500 | 1500/1500 | 1700/2000 |

Heat exchange area m2 | zero point nine | one point three | one point seven | two point eight | four point three | six point five | eight point seven |

Mixing speed r/min | 0-400rpm | ||||||

Motor power KW | zero point three seven | zero point five five | zero point seven five | one point five | two point two | four | five point five |

Weight of kettle body kg | one hundred and eighty | two hundred and fifty | three hundred and sixty | six hundred and fifty | eight hundred and fifty | one thousand one hundred and fifty | one thousand six hundred and eighty |

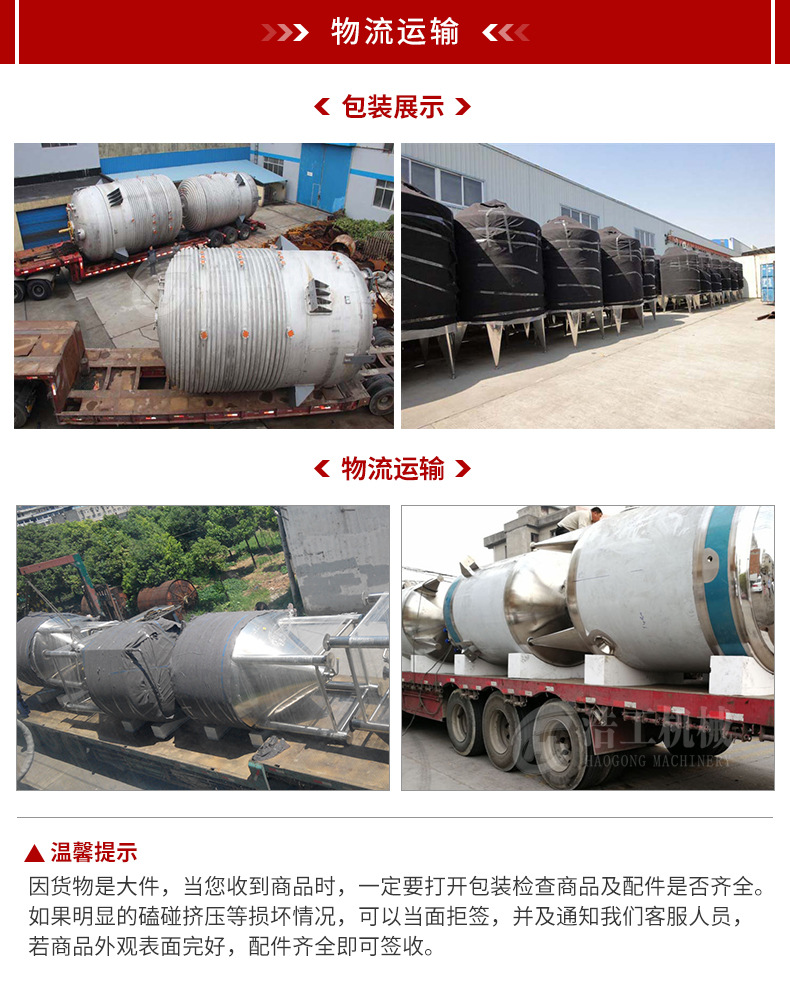

Production of physical images

Detail display:

Real shooting case:

Process flow diagram of liquid preparation system:

When you order from opencartworks.com, you will receive a confirmation email. Once your order is shipped, you will be emailed the tracking information for your order's shipment. You can choose your preferred shipping method on the Order Information page during the checkout process.

The total time it takes to receive your order is shown below:

The total delivery time is calculated from the time your order is placed until the time it is delivered to you. Total delivery time is broken down into processing time and shipping time.

Processing time: The time it takes to prepare your item(s) to ship from our warehouse. This includes preparing your items, performing quality checks, and packing for shipment.

Shipping time: The time for your item(s) to tarvel from our warehouse to your destination.

Shipping from your local warehouse is significantly faster. Some charges may apply.

In addition, the transit time depends on where you're located and where your package comes from. If you want to know more information, please contact the customer service. We will settle your problem as soon as possible. Enjoy shopping!